Condition Monitoring and Predictive Maintenance

Use Condition Monitoring to Bridge From Reactive to More Predictable Operations

Condition Monitoring (CM) and Predictive Maintenance (PdM) are the top return on investment (ROI) opportunities in manufacturing and industrial process applications. PdM delivers ROI in asset-intensive industries including manufacturing and industrial process operations.

Businesses need their assets to operate at full capacity with the lowest maintenance costs possible. CM and PdM allow this balance to occur. When asset condition data is integrated with maintenance and operations data, it gives a holistic, analytical view for predicting maintenance needs, operational anomalies, and business outcomes.

CBT Monitoring & Analytics

- Condition-indicating sensor monitoring (vibration, motor current, temperature, oil, ultrasonic, etc.)

- Predictive Analytics using Condition Monitoring and Operational data together

- Asset diagnostic tools

- Data Historian and CMMS implementation and integration, including work execution using Connected Worker

- Web-based dashboards with business and asset performance indicators

Business Benefits

- Increased production capacity

- Lower maintenance costs

- Streamlined asset management and visibility

- Lower insurance costs with improved control of assets

- The bridge between the digital and physical worlds to fully connect assets, with immediate access to all relevant data

WHITEPAPER

Unlocking the ROI Potential of Condition Monitoring & Predictive Maintenance

3-PART PODCAST SERIES

Harness the Power of Condition Monitoring and Predictive Maintenance

BROCHURE

Are You Ready? Your Plant, Digital Journey, Digital Twin, IT/OT/ET Convergence

Results

reduction in unplanned downtime & maintenance spend

increase in production & revenue

Solutions

Run to Failure

Preventative Maintenance

Condition Monitoring

Predictive Maintenance

Proactive Maintenance

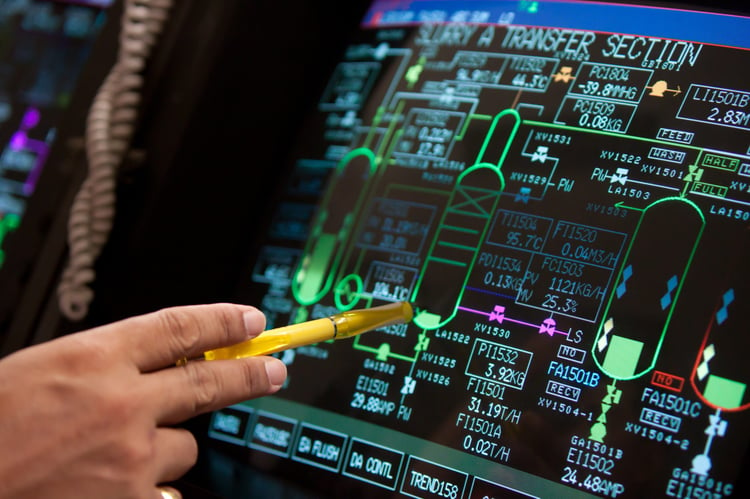

Industries

Condition Monitoring and Predictive Maintenance have real-world applications across a multitude of industries. They build a bridge from reactive maintenance with low productivity and high costs to a more predictable operation. With integration and automation, actional insights with reasons are made available to planners and decision-makers so they become more proactive. Predictive Maintenance is especially relevant in asset-intensive verticals such as Oil & Gas, Energy & Utilities, Manufacturing, Mining, Pharmaceuticals, Food & Beverage, and Chemical Processing, where it expedites decision-making by providing real-time access to critical data and analytics.

How We Do It

Innovation Delivery as a Service (IDAAS) is CBT’s proven process that de-risks innovation and gives you the best chance for digital transformation success. Delivering real results through constant evolution, transformation, rapid iteration, innovation, and support.